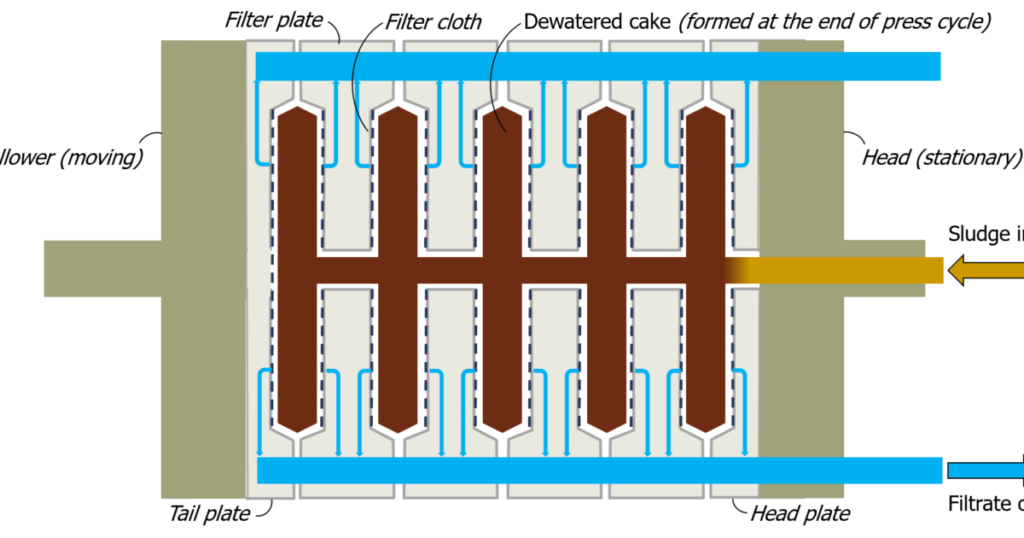

A plate and frame filter press is a type of mechanical dewatering equipment used for solid-liquid separation. The working principle of a plate and frame filter press is as follows:

- Preparatory phase: The slurry to be filtered is pumped into the filter press and distributed evenly among the filter plates.

- Filtration phase: The filter press is closed, and a hydraulic pump is used to apply pressure to the plates. The pressure forces the slurry to flow through the filter media and into the filter chambers, while the solids are retained on the filter media.

- Wash phase: After the filtration phase, the filter cake is washed with water or other cleaning agents to remove any remaining impurities.

- Drying phase: Once the washing is complete, the filter cake is dried by blowing air or applying heat.

- Discharge phase: Finally, the filter press is opened, and the filter cake is discharged from the filter plates. The process is then repeated for the next batch of slurry.

The plate and frame filter press consists of a series of filter plates and frames arranged alternately. The filter plates are covered with filter media, such as cloth or paper, which allows the slurry to pass through while retaining the solids.

The frames hold the filter plates in place and provide support for the hydraulic pump. The filter press is designed to handle a wide range of slurry types and can be used for applications such as wastewater treatment, mining, and food processing.