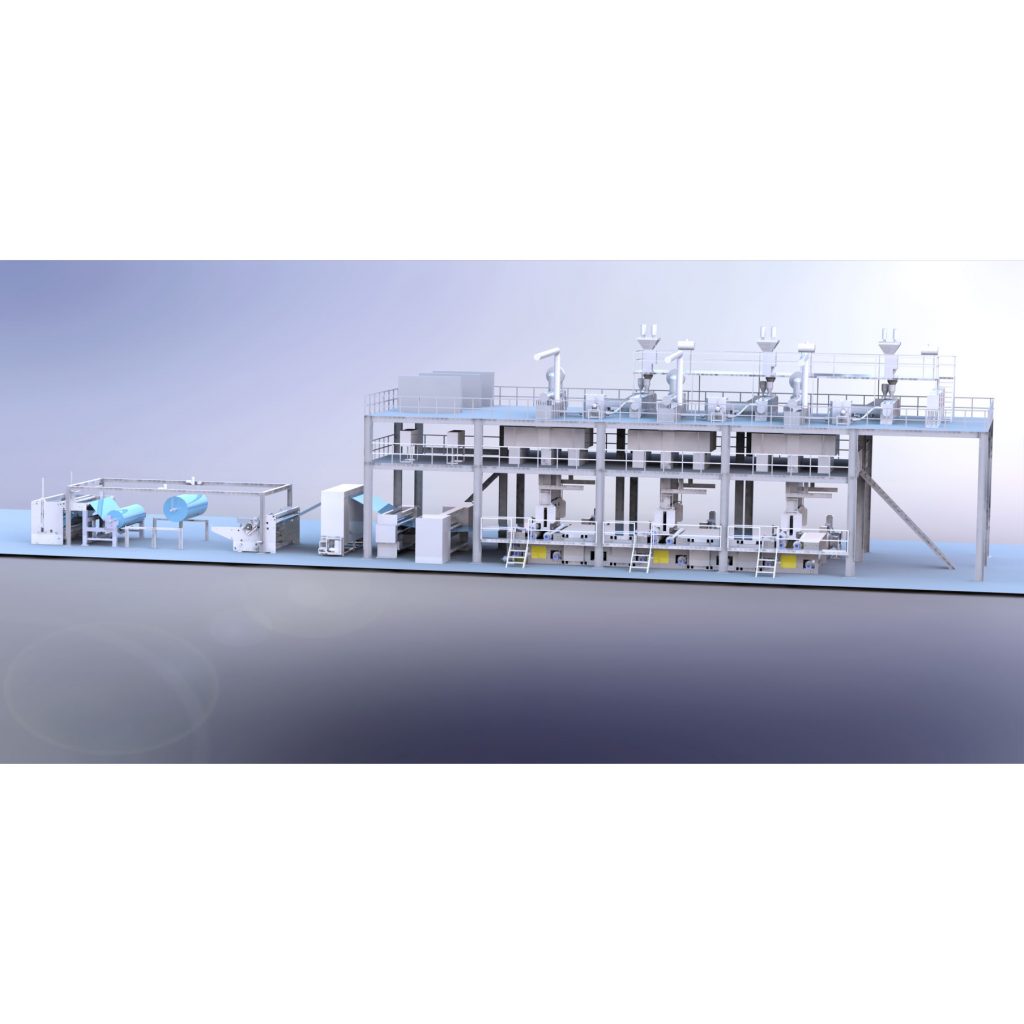

The consistency of soften blown stock is painstakingly related to the pass on head, but the handling precision of the liquefy blown bite the dust head is extremely high, and the assembling cost of the kick the bucket head is expensive. The exact assembling technique of soften blown texture is nearly complex, including many disciplines comparing to polymer science, liquid mechanics, wind stream, turning science, and so on, and the necessities for gear producing are likewise high. The key is the entire arrangement of assembling gear for soften blown material. The unrefined components is a thermoplastic counterfeit material that is liquefied and constrained via an extruder comprising of an exceptionally enormous number of small spouts. Following leaving the spouts, the individual fibers are unceremoniously passed up hot air in a similar course while regardless of their semi-liquefied state, expanding them and making exceptionally fine, vast filaments, inside two or three milliseconds.

Extremely fine strands are framed, and afterward assembled on a web shaping drum or show drapery to kind a web.

At long last, they’re built up by self-bond to create a meltblown fiber non-woven texture. Plastic extruders are accessible different sorts, and you can sort via each style with Alibaba’s web search tool. Many relax blown machine are tailor-made to be utilized in pipe creation, and you’ll set them to make anything that determinations of line be great for you. While picking a line making machine, make sure that it might conceivably manage the plastic materials you use, and look at yield charges to ensure it has the creation capacity required. On the other hand, you would go for a blow film extruder to make plastic sheets and movies – a superb choice inside the food bundling industry.

It is seen abroad in light of the fact that the most limited stream polymer one-step fabricating course of. Jwell administration architects will continuously be hanging around for something you wanted. This sort of spout is little in aspect, and it is fundamental for process an extravagant opening on the little spout, which is uncommonly hard to process and gets some margin to process. Was laid out in 2010, shares got recorded on the Athens Stock Exchange in 1995, which expecting every one of the Technical Fabrics’ activities of Thrace Plastics. Today Thrace NG is creating PP specialized textures and yarns/filaments. Having an exorbitantly lengthy acknowledgment distance will prompt a reduction in the vertical and flat power and bowing power.

It has been in wide use in clinical garments, pack and construction, etc. Jwell Machinery Co., Ltd sets up in 1997 , we’re goliath maker of plastic expulsion hardware in China, our headoffice was situated in Shanghai. On Time Delivery Of Spare Parts We melt blown fabric machine have practically all vital parts of our items in stock and We remotely screen the cloud status of the machine and supply very much planned upkeep ideas ,we guarantee your extruder will work constantly . Top notch Jwell machine barrels , screws , T-pass on and roller without anyone else , we the board the machine great from attracting plan to last establishment .

Following this cure, veils ought to be permitted to look for a timespan days until the ethylene oxide degree disperses, as the material is poisonous to the human constitution as well as being combustible. To concentrate on key firms that produce non-woven textures, see our related data Top Manufacturers and Suppliers of Non-Woven Fabrics. To see different aides and articles related to PPE comparing to veils, respirators, goggles, gloves, outfits, or PAPRs, a stock shows up toward the finish of this article. The soften blown fiber is uniformly acquired and unfurl on the net and moved forward. There is a pull fan underneath it to release the new air descending from the top.

Embrace specific coat holder type and fuel leveling sort turning kick the bucket with fair-minded licensed innovation privileges, and the dissolve appropriation is even. Change become more less difficult and solid, and the machine can adjust to various crude supplies to acquire extra broadly use. The web by negative strain, make into PP turned fortified non-woven texture, the item is included by uniform cowl, decent profundity, great ventilation and positive sentiment, etc.

It is reasonable for assembling clinical veils, N95 covers and different high-grade covers. In 2020, the world are confronting the exceptionally terrible infection going after, great veils are successful supplies for all times wellbeing, the abruptly prerequisites make the large absence of mellow blown texture for covers creation. FAYGOUNION Machinery firm is an association with social obligations, we are making an honest effort to contribute a small strain to work with the world people on the whole for better life.