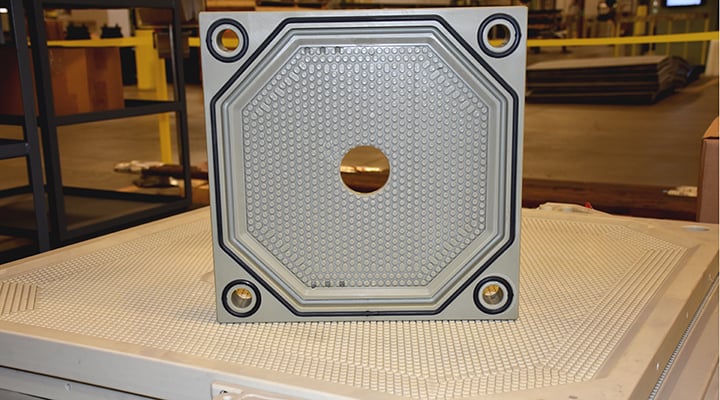

Filter press plate sizes play a crucial role in optimizing filtration efficiency. This article provides insights into the significance, types, and considerations related to filter press plate sizes. From understanding their impact on filtration capacity to exploring different plate size options, we delve into the key aspects that enable efficient and effective filtration processes.

The Importance of Filter Press Plate Sizes

Filter press plate sizes directly influence the filtration capacity and overall performance of a filter press system. Choosing the appropriate plate size is essential for maximizing productivity and achieving desired filtration outcomes.

Types of Filter Press Plate Sizes

- Standard Plate Sizes: Filter press plate sizes are available in standard dimensions, such as 400mm, 630mm, 800mm, and 1200mm, catering to various filtration requirements.

- Custom Plate Sizes: Manufacturers also offer the flexibility to customize plate sizes based on specific filtration needs, providing tailored solutions for unique applications.

- Recessed Chamber vs. Membrane Plates: Both recessed chamber and membrane filter press plates come in different sizes, allowing for different cake capacities and filtration processes.

Considerations for Selecting Filter Press Plate Sizes

- Filtration Volume: The desired filtration volume influences the selection of filter press plate sizes, as larger plates accommodate higher volumes.

- Filtration Speed: The speed at which filtration needs to be completed affects the choice of plate sizes, as larger plates generally result in faster filtration rates.

- Cake Thickness: The desired thickness of the filter cake also plays a role in determining the appropriate plate size, as it affects the efficiency of cake removal during the filtration process.

- Available Space: The physical space available for the filter press system should be considered when selecting plate sizes, ensuring proper installation and operation.

Applications and Benefits of Different Filter Press Plate Sizes

- Small Plate Sizes: Smaller plates, such as 400mm and 630mm, are commonly used in laboratory-scale filtration, small-scale production, and applications where space is limited.

- Medium Plate Sizes: Plates ranging from 800mm to 1200mm are suitable for medium-scale filtration processes in industries like pharmaceuticals, chemicals, and food and beverage.

- Large Plate Sizes: Filter press systems with large plates, such as 1500mm and above, are utilized in industries with high-volume filtration requirements, including mining, metallurgy, and wastewater treatment.

Conclusion

In conclusion, choosing the right filter press plate size is essential for optimizing filtration efficiency. By understanding the importance of plate sizes and considering factors such as filtration volume, speed, cake thickness, and available space, operators can select the most suitable plate sizes for their specific applications. Whether using standard sizes or customizing plate dimensions, the appropriate filter press plate sizes contribute to enhanced productivity, improved filtration outcomes, and efficient filtration processes.