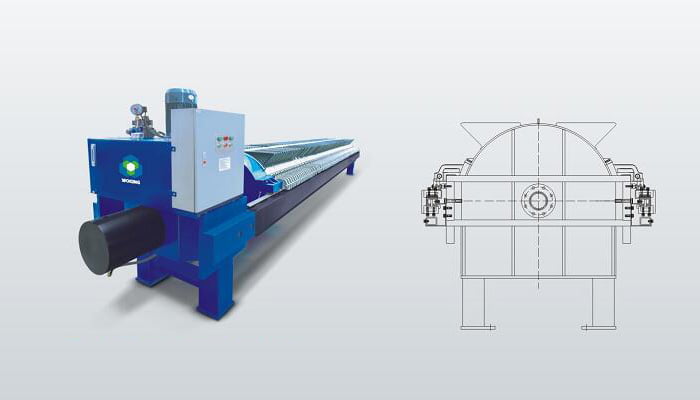

Filter press machines play a pivotal role in various industries by facilitating efficient solid-liquid separation processes. This article provides valuable insights into the importance of filter press machines, their benefits, and considerations for selecting the right equipment.

The Significance of Filter Press Machines

Filter press machines offer several advantages for efficient solid-liquid separation:

Enhanced Filtration Efficiency: These machines utilize pressure to separate solids from liquids, ensuring high filtration efficiency and improved product quality.

Increased Throughput and Reduced Cycle Times: Filter press machines enable quick and continuous filtration, resulting in increased throughput and reduced processing time.

Cost Savings: By effectively separating solids from liquids, filter press machines minimize waste generation, leading to cost savings in disposal and treatment processes.

Selecting the Right Filter Press Machine

Consider the following factors when choosing a filter press machine:

Capacity and Size: Evaluate the required processing capacity and choose a machine that can handle the anticipated volume of solids and liquids.

Filtration Efficiency: Assess the machine’s filtration efficiency, including factors such as cake moisture content, solids retention, and clarity of the filtrate.

Automation and Control: Opt for machines equipped with advanced automation and control systems for precise operation, data logging, and process optimization.

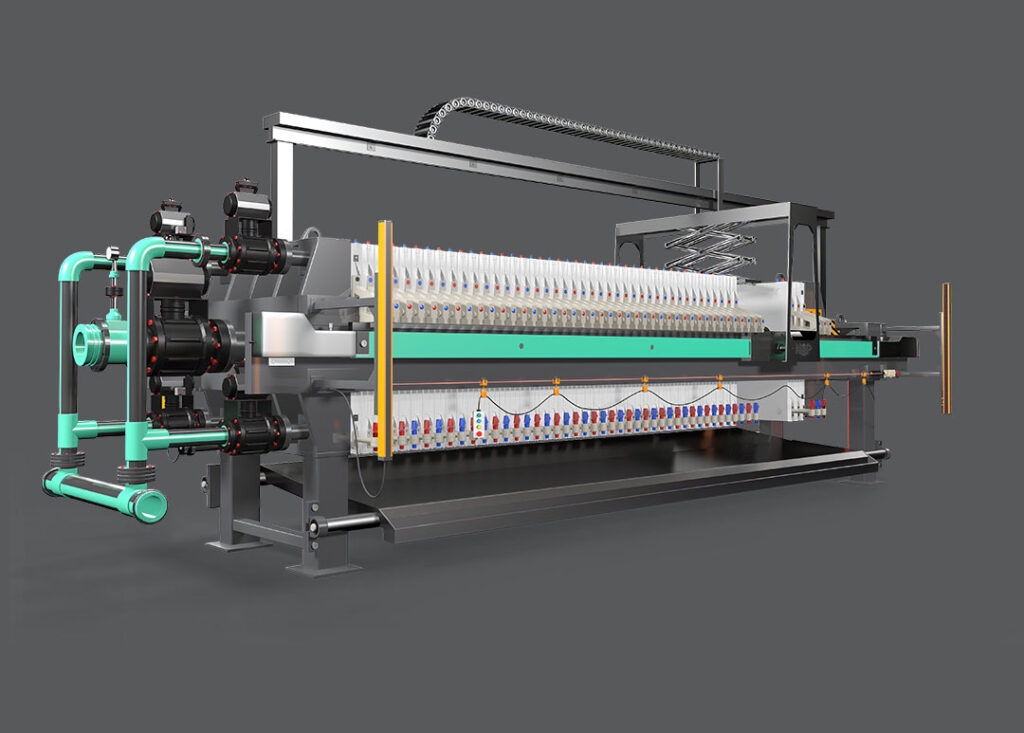

Advanced Features and Technologies in Filter Press Machines

Modern filter press machines incorporate innovative features and technologies to enhance performance:

Membrane Technology: Some machines utilize membrane filter plates that allow for additional squeezing of the filter cake, resulting in drier solids and improved filtration efficiency.

Automatic Cloth Washing: Advanced machines feature automatic cloth washing systems, ensuring optimal cloth performance and prolonged lifespan.

PLC Control Systems: Programmable Logic Controller (PLC) systems enable precise control, monitoring, and data logging, streamlining filtration processes and facilitating troubleshooting.

Example of Filter Press Machine Application

In the mining industry, a filter press machine is used to separate solids from a slurry, extracting valuable minerals.

The machine applies pressure to the slurry, forcing the separation of solids and liquids. The resulting filter cake contains concentrated minerals, while the filtrate can be further processed or safely discharged.

Conclusion

Filter press machines play a crucial role in efficient solid-liquid separation processes, offering enhanced filtration efficiency, increased throughput, and cost savings. When selecting a filter press machine, consider factors such as capacity, filtration efficiency, and automation features.

Advanced technologies like membrane plates, automatic cloth washing, and PLC control systems further enhance machine performance. In the mining industry, filter press machines are utilized to extract valuable minerals from slurry. By leveraging advanced filter press machines, industries can achieve optimal results in their solid-liquid separation operations.