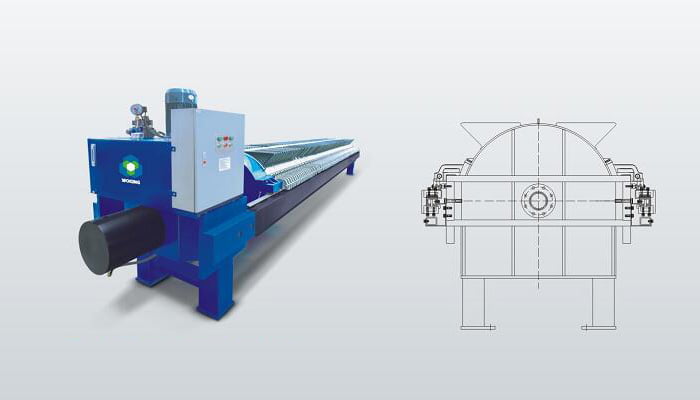

In this article, we will explore the role of filter presses in wastewater treatment, their benefits, and how they can help improve the efficiency and effectiveness of wastewater treatment plants.

How Filter Presses in Wastewater Treatment work

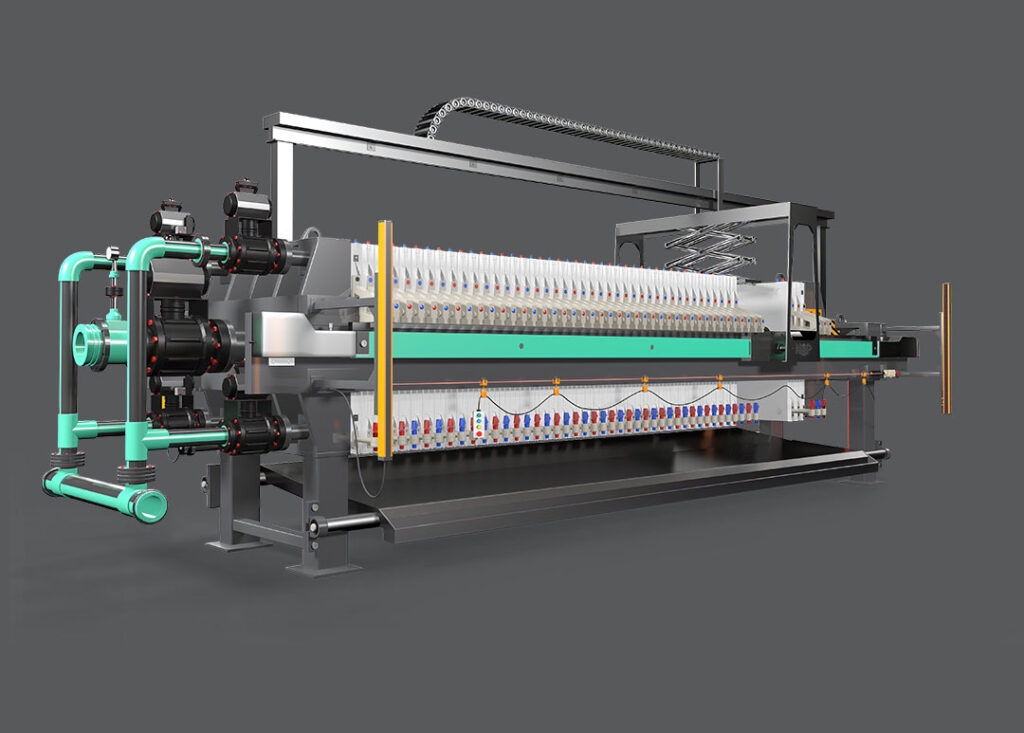

A filter press consists of a series of plates and frames that are stacked together to form a filtering system. The wastewater is pumped into the filter press, and the solids are separated from the liquids as they pass through the filter media.

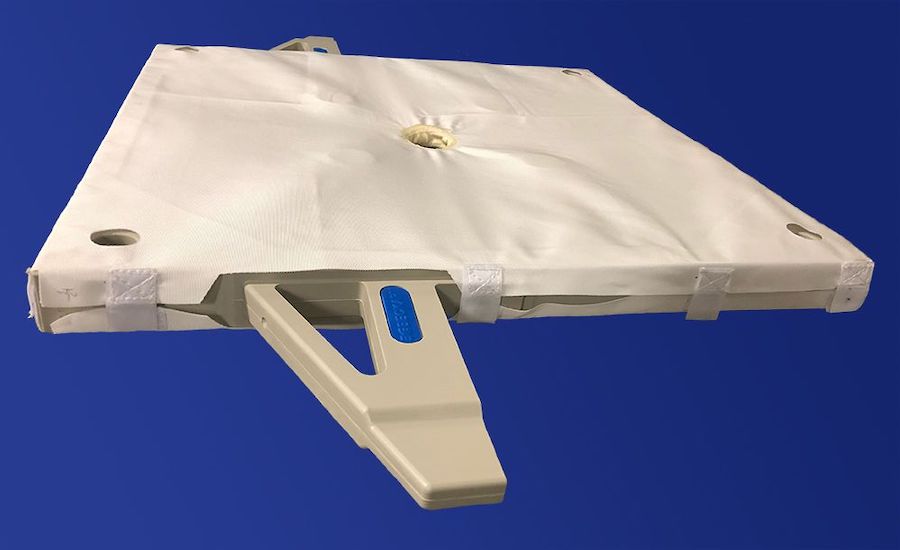

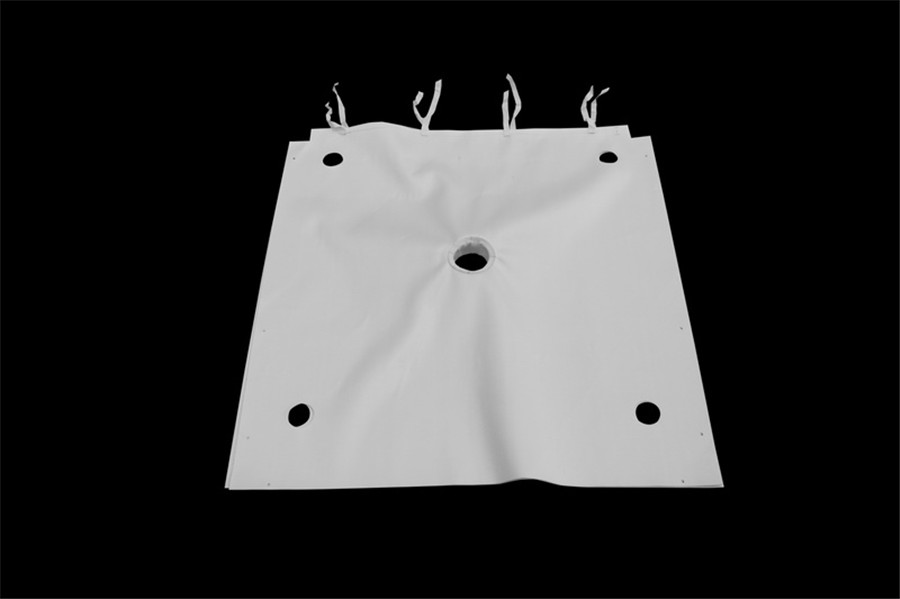

The filter media is typically made of a synthetic material, such as polypropylene or polyester, which has a specific pore size that allows the solids to be captured while allowing the liquids to pass through.

Benefits of Using Filter Presses in Wastewater Treatment

The use of filter presses in wastewater treatment offers several benefits, including:

- High-quality filtrate: The filter press produces a high-quality filtrate that is free from impurities and contaminants, making it safe for discharge into the environment.

- Increased efficiency: The filter press can significantly increase the efficiency of wastewater treatment plants by reducing the amount of solids that need to be treated.

- Cost savings: The use of a filter press can save costs by reducing the amount of chemicals and energy required for treatment.

- Compact design: The filter press is a compact device that can be easily installed in wastewater treatment plants, making it an ideal solution for plants with limited space.

Types of Filter Presses Used in Wastewater Treatment

There are several types of filter presses used in wastewater treatment, including:

- Plate and frame filter press: This is the most common type of filter press used in wastewater treatment. It consists of a series of plates and frames that are stacked together to form a filtering system.

- Membrane filter press: This type of filter press uses a membrane filter media that is designed to capture very small particles and produce a high-quality filtrate.

- Recessed chamber filter press: This type of filter press has a recessed chamber that allows for a higher concentration of solids in the feed stream, making it ideal for treating wastewater with high solids concentrations.

Applications of Filter Presses in Wastewater Treatment

Filter presses are commonly used in a variety of wastewater treatment applications, including:

- Primary treatment: Filter presses can be used to remove large solids and debris from wastewater during primary treatment.

- Secondary treatment: Filter presses can be used to remove suspended solids and bacteria from wastewater during secondary treatment.

- Tertiary treatment: Filter presses can be used to remove nutrients and other contaminants from wastewater during tertiary treatment.

Maintenance and Troubleshooting of Filter Presses

To ensure the optimal performance of a filter press, regular maintenance and troubleshooting are necessary. Some common maintenance tasks include:

- Cleaning the filter media: The filter media should be cleaned regularly to remove any debris or contaminants that may accumulate.

- Replacing the filter media: The filter media should be replaced periodically to ensure that the filter press continues to produce high-quality filtrate.

- Checking the pressure: The pressure in the filter press should be checked regularly to ensure that it is within the recommended operating range.

In conclusion, the use of a filter press in wastewater treatment is a crucial step in removing impurities and contaminants from wastewater.

The filter press produces a high-quality filtrate that can be safely discharged into the environment, and it offers several benefits, including increased efficiency, cost savings, and compact design.

There are several types of filter presses used in wastewater treatment, and they can be applied in various treatment processes. Regular maintenance and troubleshooting are necessary to ensure the optimal performance of a filter press.